We will get back to you shortly

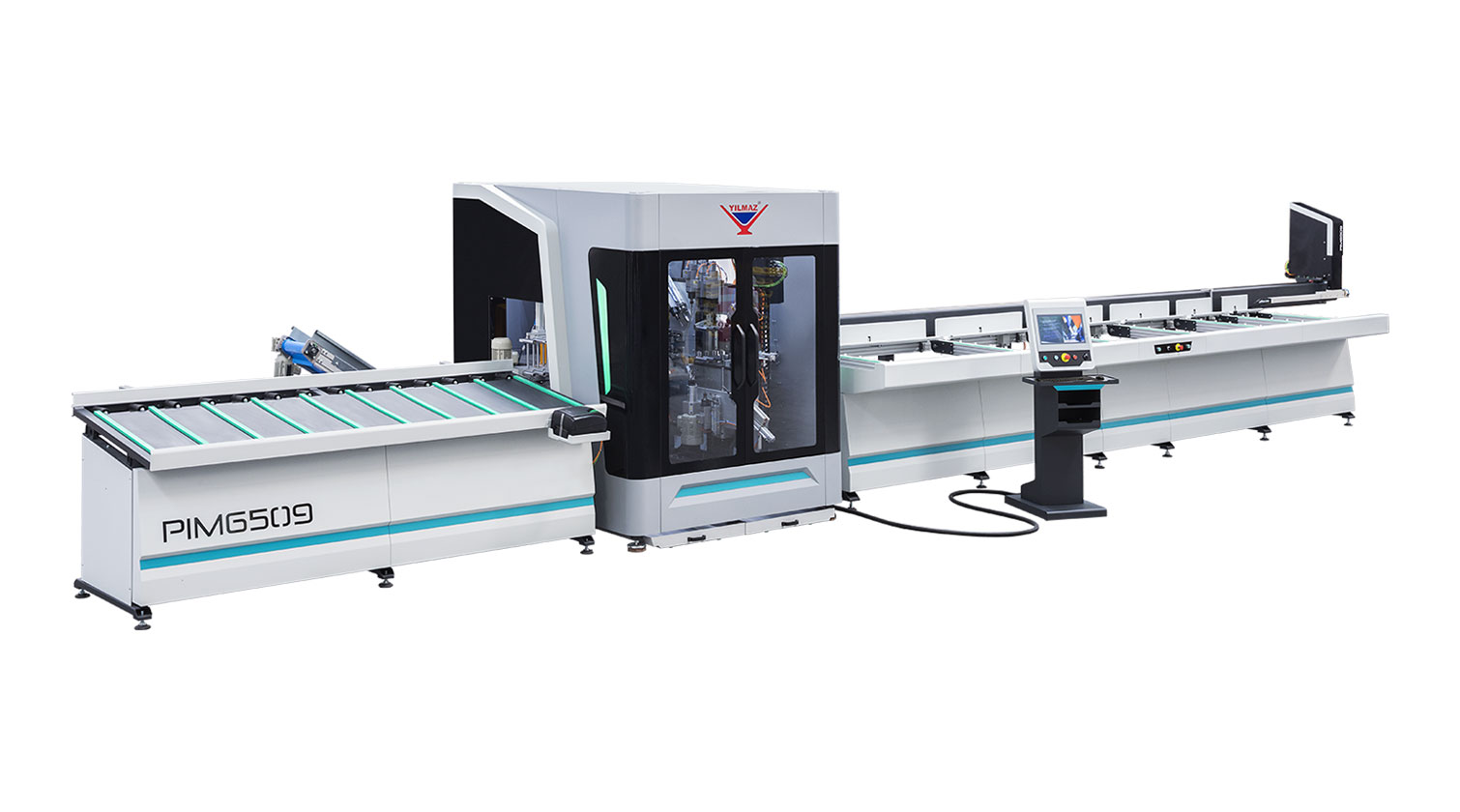

PVC Profile Fabrication Centre | YILMAZ PIM 6509

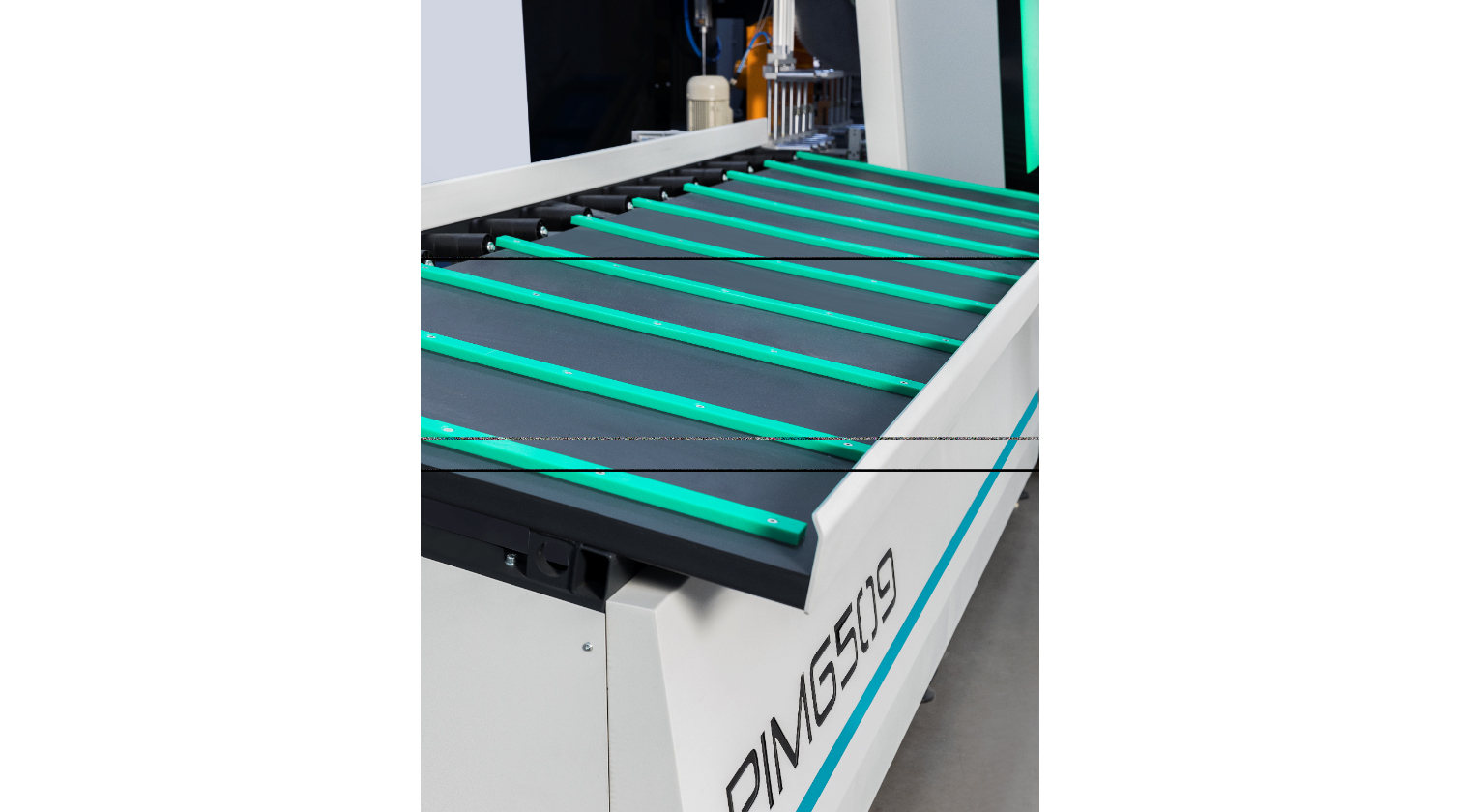

PIM 6509 is 8-axis CNC controlled machining center specifically designed to process PVC window profiles. The machine can perform operations on four sides of PVC profiles such as milling, cutting key holes, water slots, hinge holes, handle holes, marking, saw blade cutting etc. PIM 6509 has cutting list optimization feature to maximize the yield. 7 pieces of PVC profiles can be placed on the infeed conveyor of the machine and 3-axis gripper arm moves them into the milling & cutting stations. Operator attaches barcode labels on the processed profiles to make them ready for welding operation.

Product PDF

- Servo control system providing CNC motion at 8-axis

- Fully automated feeding, carrying, positioning, cutting and transferring units

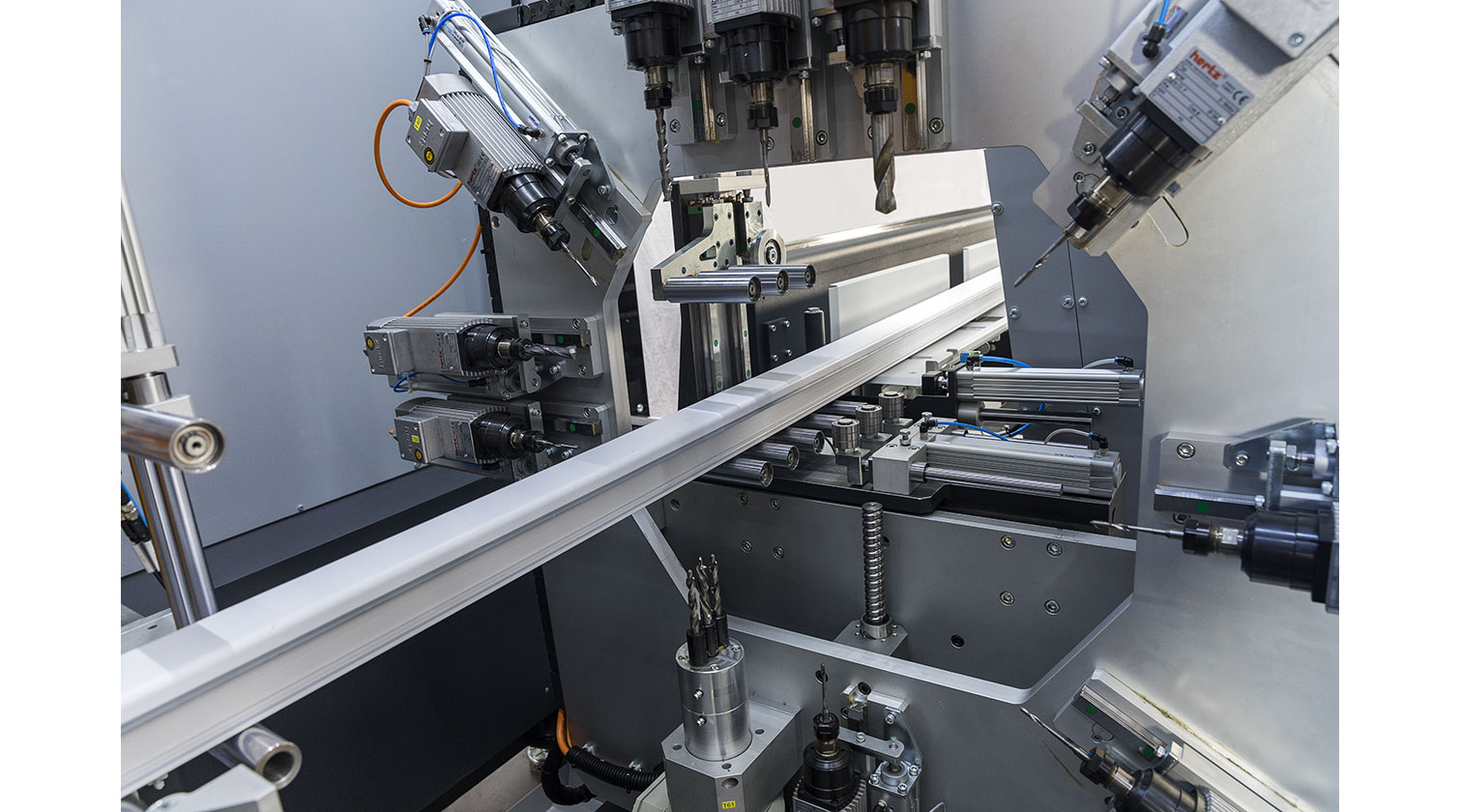

- Performing operations on four sides of PVC profiles such as milling, key holes, water slots, hinge holes, handle holes, marking, saw blade cutting etc.

- 3 Axis gripper arm for accurate profile feeding

- Horizontal and vertical clamps during the sawing operation

- 7 Profiles capacity infeed magazine

- Servo controlled top-fed saw blade with Ø 550 mm dia. that rotates between the range of 30⁰ and 150⁰

- Windows based PC and 15.6’’ LCD touch screen monitor

- Remote desktop connection and providing technical support

- User friendly interface that is compatible with CAD software

- Easy integration with the CNC welding and corner cleaning machines

- Automatic frame and sash profile recognition system

- Automatic profile width and height dimension control system

- Automatic lubrication system

- Low pressure control for saw blade safety operations

- LED interior lighting

- Barcode-Scanner

- Angled chip conveyor

- Chip collector

- Workshop logistic equipment

- Additional saw blade and tools