We will get back to you shortly

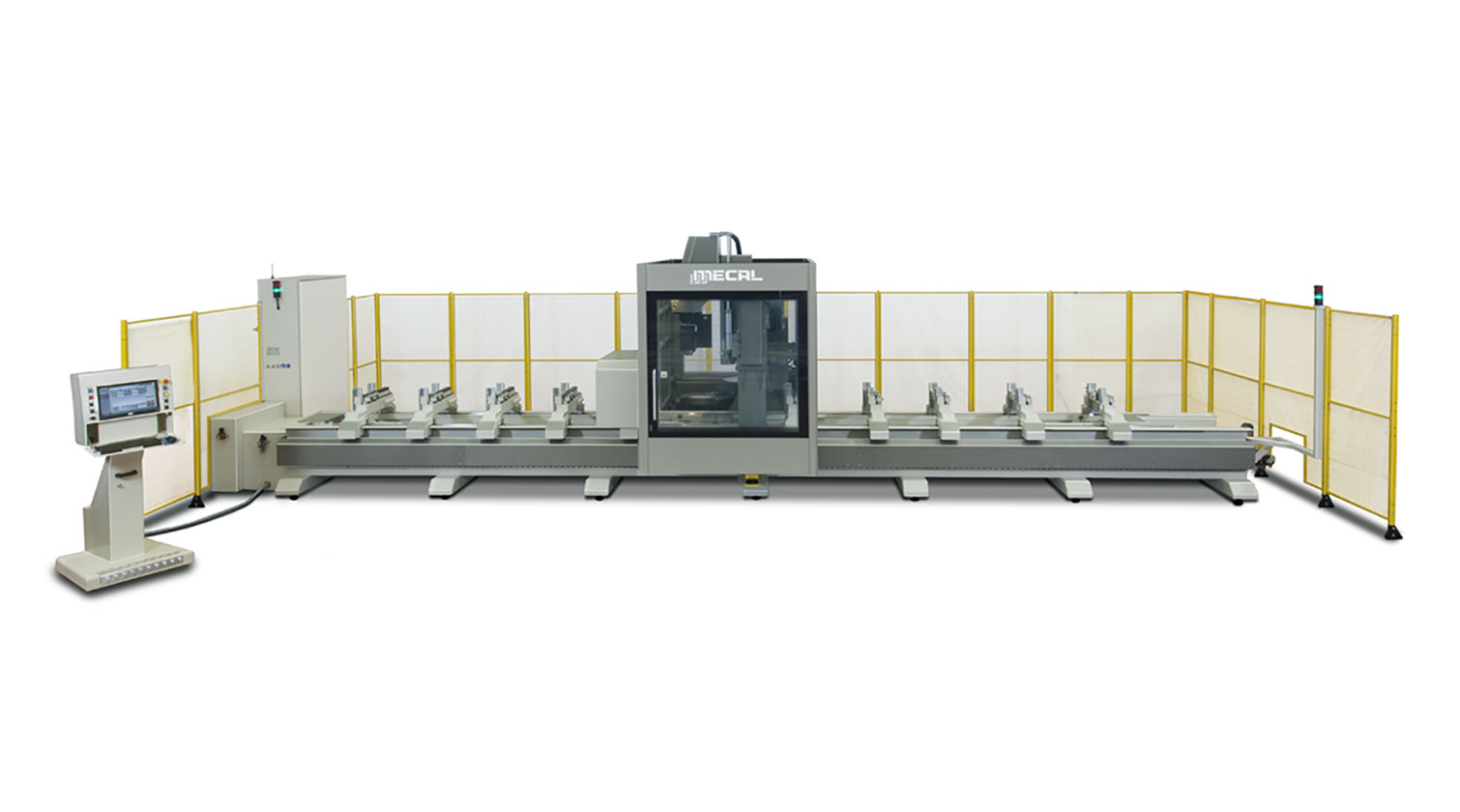

CNC Profile Machining Center | MECAL GEOS-5

The Mecal “Geos” CNC machining centre is a 5 axis CNC and features a 12 kW electro-spindle, 18 tools magazine and automatic clamp positioning system. The “Geos” has been designed for the heavy duty work on long aluminum, light alloys extrusions and light gage steel. It is the perfect solution for the production of big size curtain walls and other complex aluminum extrusion processing.

Two machining zones can be used independently (pendular mode) so that loading/unloading times are masked and machining length is used efficiently.

GENERAL

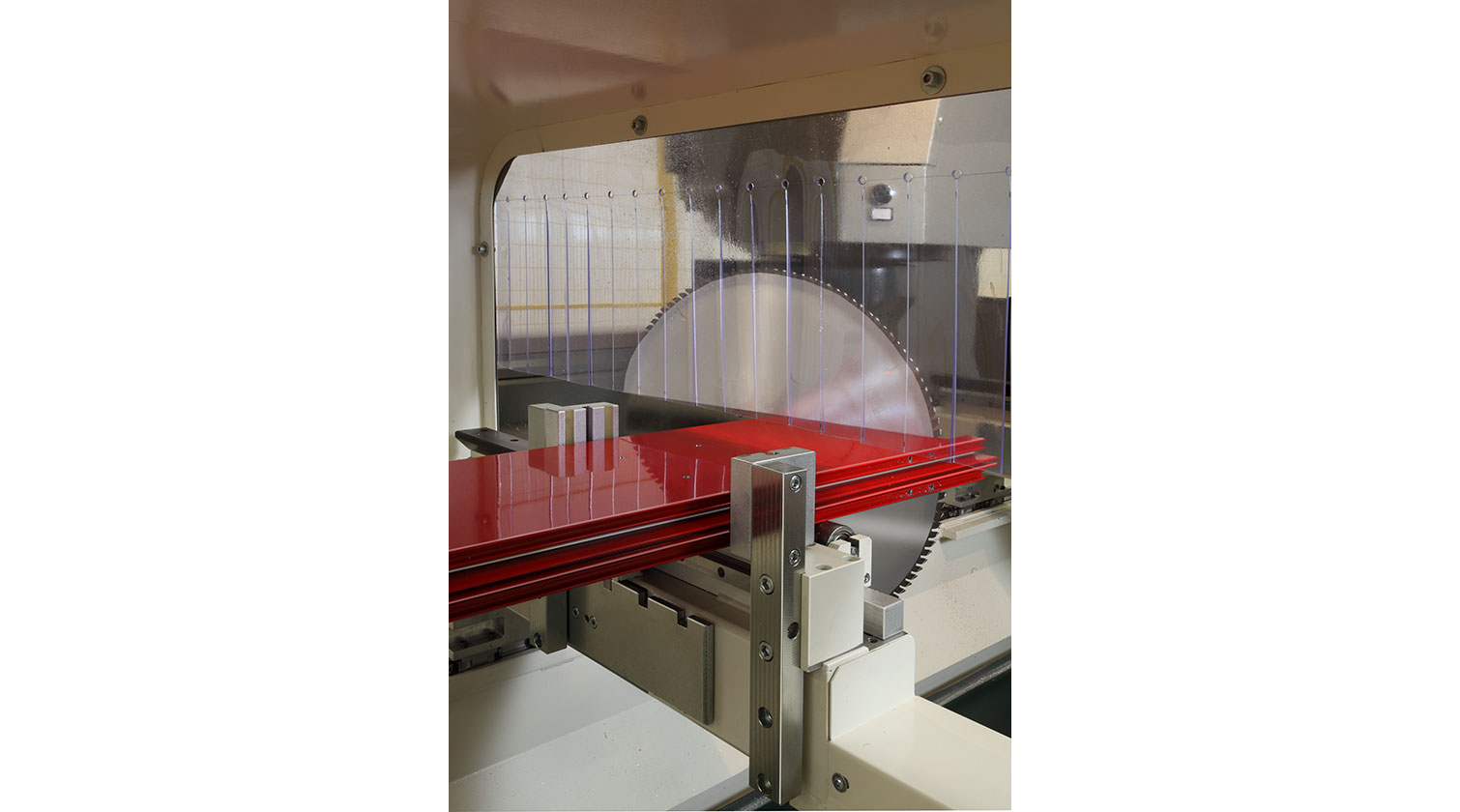

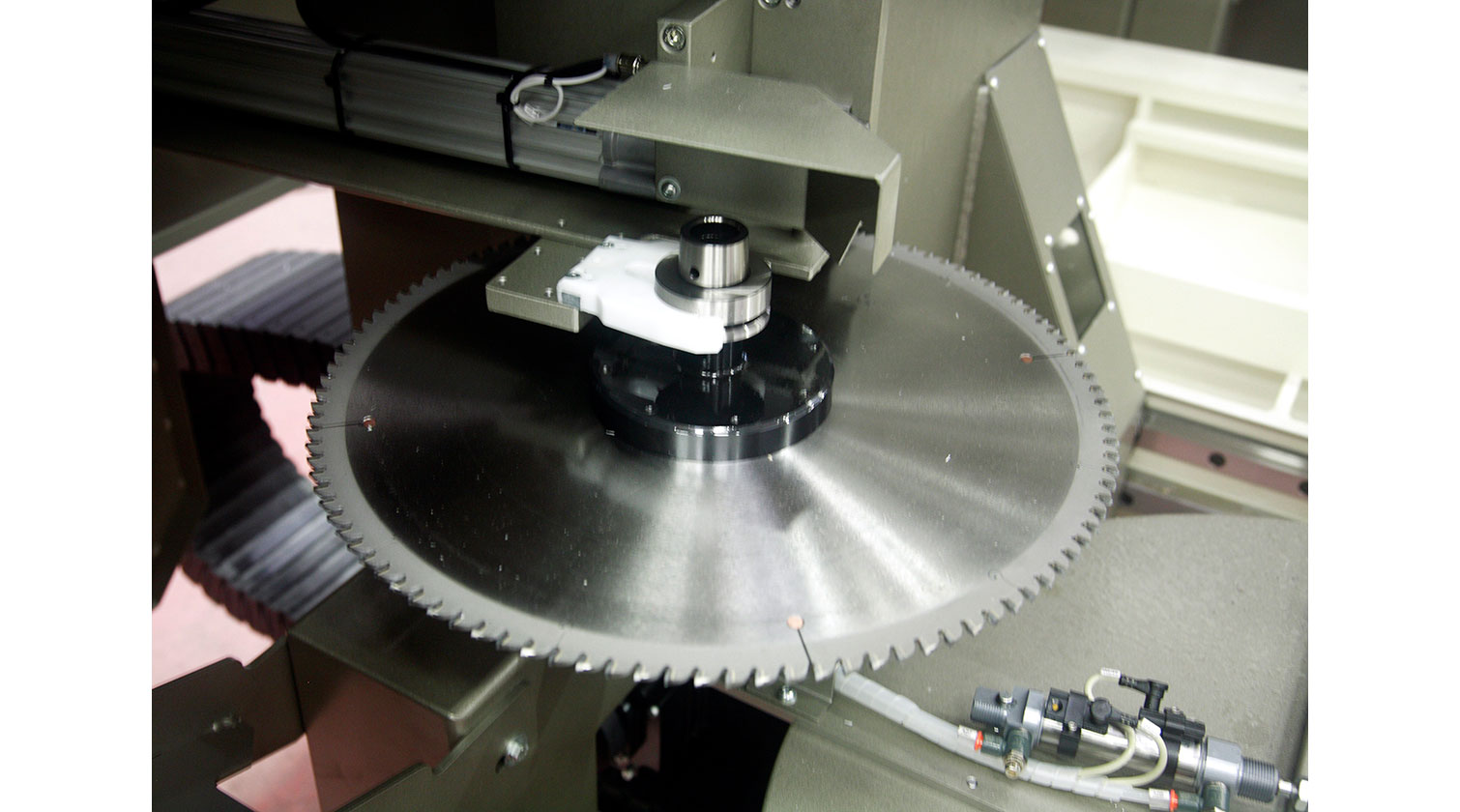

Mecal Geos-5 is a gantry type vertical spindle 5 axis aluminum CNC machining centre. The machine can work with extruded aluminum, light alloy and light steel materials. It has a 10 kW, 24000 rpm electro-spindle with HSK-F63 tool holder system. Main rotary tool magazine has 18 slots. A separate blade holder for the main 500mm saw blade is located at the back of the gantry.

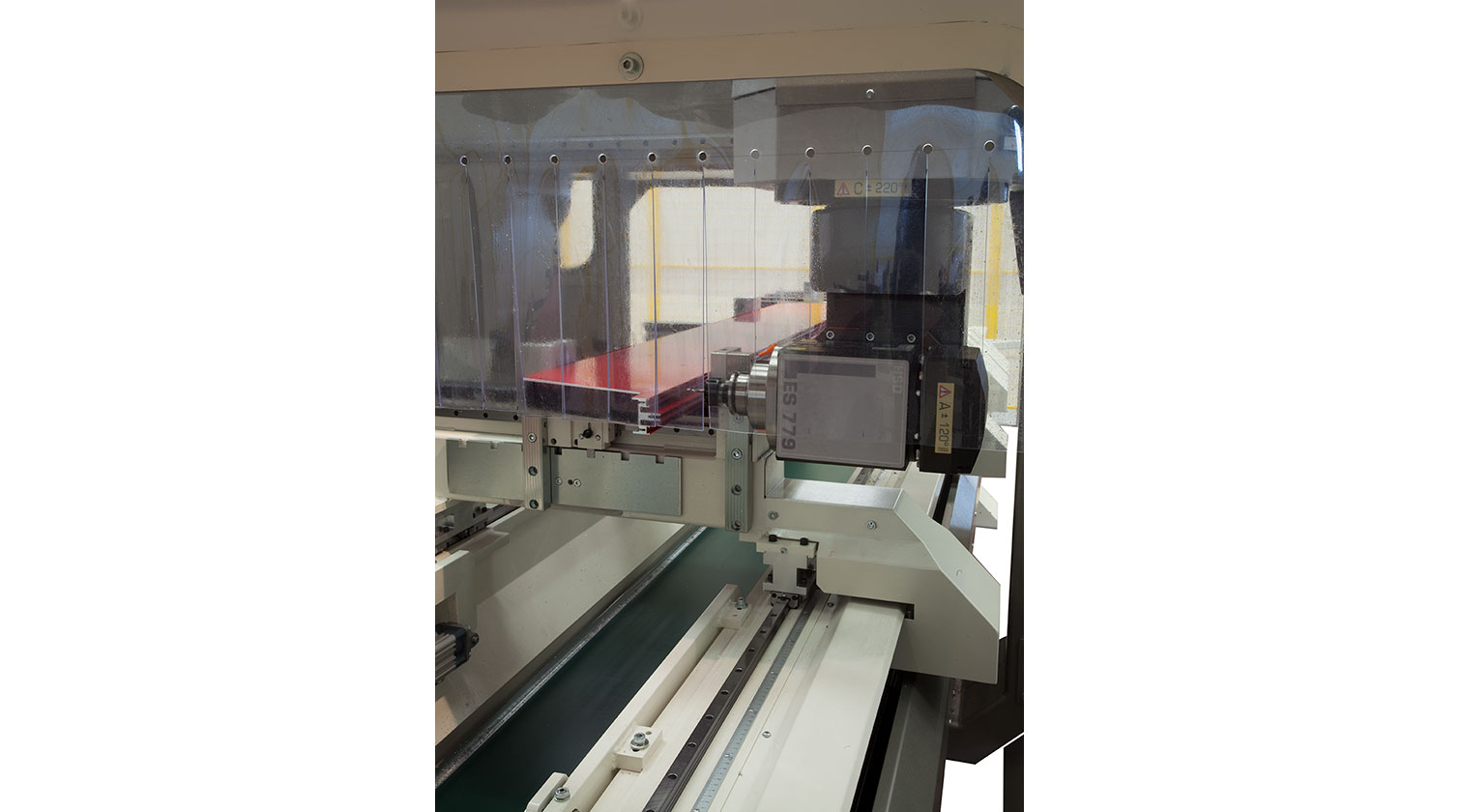

CNC unit allows linear and circular interpolation on 3 axes. A and C axes are the spindle rotation axes. A axis is the spindle tilt and range ±120°. C axis is spindle rotation around Z-axis within ±220°.

Using a drill, milling bit or a tap, it is possible to work on 5 sides of the profile. Machine can perform end-milling operations by using milling cutter and compound miter cuts by using a saw blade.

The machine can work in two independent zones (pendular mode) that allows the operator to load and unload workpieces safely while the machine is still processing in the other zone.

The 2 pneumatically operated reference stops are standard and located on each end of the machine. Intermediate reference stops are available as a pair in order to have 4 zones for machining 4 parts in the same cycle or 2 pairs in pendulum mode.

CLAMPING

The Geos 5 axis aluminum CNC machine can be equipped with self motorized (MMI) or self motorized cut-and-separate (MDT) clamps. Both type of clamps are capable to go to calculated positions independently, simultaneously and rapidly. The clamps can change position during the cycle (MAM). This may be necessary in for machining dense parts. The MAM feature is OPTIONAL on the “Geos MMI”, while is standard on the “Geos MDT”.

PROGRAMMING

Programming both with Mecal ISO programming language or Mecal CAD3D graphic CAD/CAM software are standard. Optional STEP/IGES driver CADLink is available for companies prefer to work with a third party 3D design software. For more demanding industrial applications, Geos 5 axis CNC aluminum machining centre can be equipped with Mitsubishi CNC controller that allows all standard ISO functions.

- Gantry type vertical spindle CNC machining centre

- Electro-welded sturdy machine base is engineered for maximum rigidity and precision

- Powerful 12 kW, liquid cooled electric spindle with HSK F 63 tool holder and encoder enables execution of rigid tapping (up to M20)

- 18 tools capacity rotating tool magazine is mounted on the carriage and travels with it. This allows significantly quick tool change operations during machining. A separate tool changer for saw blade is also located on the carriage (max diameter: Ø 500 mm)

- Axes drive system is consisting of a servo controller and a brushless DC servomotor. Position is tracked by an incremental encoder integrated in the drive motor

- Work piece clamps slide on precision linear guide rails and are positioned independently on CNC controlled axes (MDT configuration). This enables to cut and separate profiles in multiple pieces than machine each piece in the same cycle.

- Clamps with quick adjustment

- Internal data transmission through optical cables to ensure fast-reacting, flawless functioning of the machine

- Working area can be divided in two zones so that two separate working stations can be utilized

- By using the disc cutter, it is possible to carry out end-milling operations on both the ends of the work piece

- Milling operations are performed with linear and circular interpolation of the X-Y-Z axes

- Pneumatically operated flipping reference stops

- Tool magazine is mounted on the mobile upright beam and travels with it. This allows a quick tool change operation during machining

- Tool cooling via Minimum Quantity Lubrication (MQL) system

- All slide ways and ball screws are lubricated through an automatic central lubrication system

- Front light curtains and side/rear safety metal screens

- Available standard lengths: 8.6m (28.2') / 10.6m (34.8') / 12.6m (41.3') / 15.7m (51.5')

- Longer versions are available

- Spindle power:12kW

- Spindle rotation speed variably up to 24000 rpm

- Tool clamping system is HSK-F63

- 18 positions tool magazine

- Large working cross-section on MDT (WxH): 550x320mm (21.6"x12.6")

- Large working cross-section on MMI (WxH): 650x320mm (25.6"x12.6")

- Max saw blade diameter: 500mm (19.7") - only on 5 axis version

- Clamps open to a fix stroke and accommodate components up to max. 650mm (25.6") width

- Electronic NC interface with a PC running on Windows 10 OS.

- Electrospindle liquid cooled, HSK-F63, 24000 rpm, 12 kW

- Tool magazine with 18 tools capacity

- Saw blade ∅ 500mm (19.7")

- 8 x Pneumatic clamps

- Drawers for chips collection

- Startup tool kit

- Front safety scanner and side/rear safety metal screens

- Electronic NC interface with a PC running on Windows 10 OS.

- CAD CAM 3D Graphic software

- Extra clamps (MMI or MDT)

- Set of two intermediate stops to allow working with max 4 parts loaded on the machine

- Probe for the automatic detection of the tool length

- Bar code reader

- CAM 3D Machining simulator

- Belt conveyor for chips and scrap pieces removal

- Interface drive for third party window making software

- CADLink 3D Driver to import STEP or IGES files

- Horizontal 2 spindle aggregate

- Saw blade aggregate Ø 120 – 215 mm (∅ 4¾" - 8.46")

- KEBA advanced remote controller