We will get back to you shortly

Profile Cutting Center | YILMAZ PCC 6505

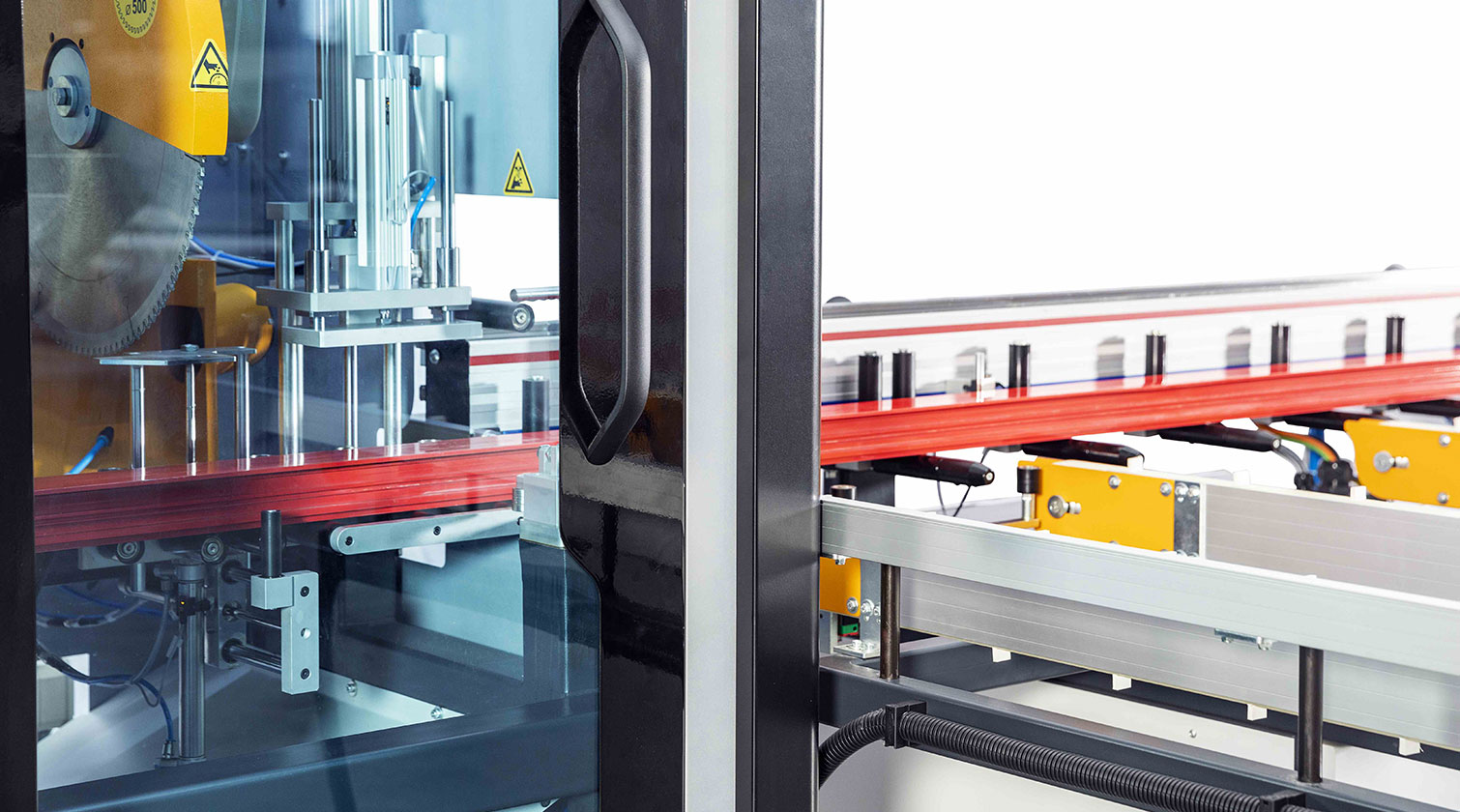

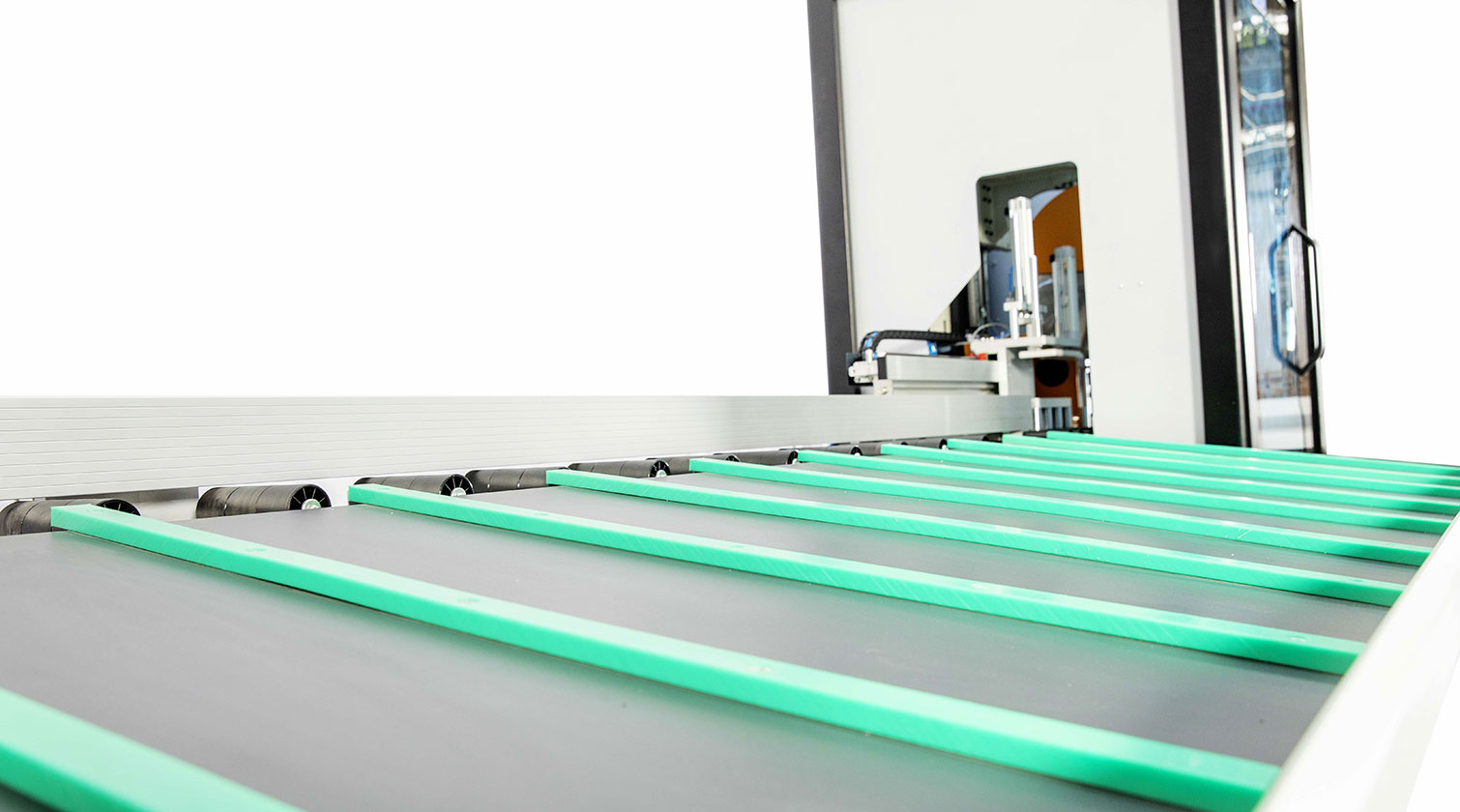

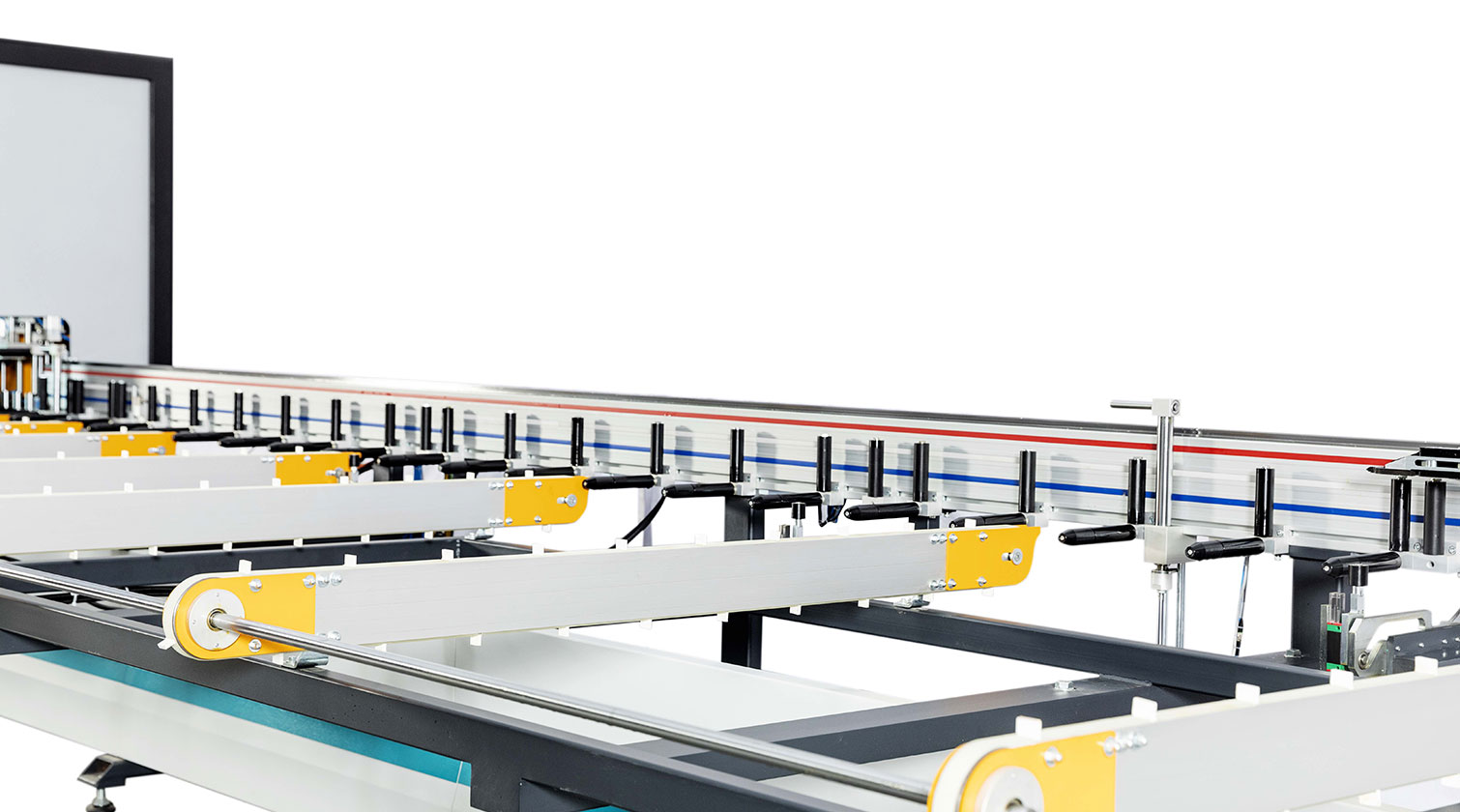

Yilmaz PCC 6505 is a 5 axis servo controlled automatic cutting machine suitable for the most of the PVC and aluminum profile types in the market. It is composed of an in-feed buffer station (magazine), servo pusher with servo adjusted gripper arm, cutting station and out-feed conveyor.

Operator places 10 pieces of profiles on the feeding conveyor of the machine and presses on the start button. The pusher adjusts itself automatically to optimum gripping position for the particular profile and starts feeding it through. Machine obtains the length and angle data from a cutting list (either created on the machine or imported from a third party software). After the profile is positioned, saw blade adjusts to any requested angle within 45°-135° then executes the cut. Cut parts are ejected onto the out-feed conveyor by means of a pneumatic gripper arm. Operator attaches barcodes (optional) on the processed parts to make them ready for the assembly. Depending on the length, the remaining pieces can be ejected on the out-feed conveyor or dropped on the waste conveyor.

- PCC 6505 is composed of an in-feed buffer station, servo pusher with servo adjusted gripper arm, cutting station and out-feed conveyor

- 5 axes YASKAWA servo control system

- Protection cabinet provides completely enclosed cutting area and full access for maintenance

- Fully automatic feeding, carrying, positioning, cutting and transferring the profiles

- Automatic in-feed magazine with a capacity of 10 profiles

- Windows based PC and 15’’ LCD industrial touch screen colour monitor

- Remote connection capability for service and software updates

- Machine interface can easily be integrated to any third party software

- Windows frame and sash recognition system for verification of correct profile loading as per the cut list

- Profile width and height dimension control system for verification of correct profile loading

- Flat type of scrap conveyor to eject scrap to the rear of the machine

- Automatic centralized lubrication system for axis screws, linear guide and bearings

- Spray mist saw blade lubrication

- Low pressure control for saw blade safety

- LED interior lighting for better visibility

- Safety interlock systems

- Safety fence around the machine

- 7kW, 400V, 3Phase Motor

- ∅ 500mm (19.7") saw blade with down-stroke motion

- Max profile length: 6500mm (21.3')

- Min profile dimensions (WxH): 40x40mm (1.57"x1.57")

- Max profile dimensions (WxH): 130x180mm (5.1"x7")

- Servo saw blade unit rotating between the range of 45° and 135° with accuracy of -/+ 0.1°

- 5 axes YASKAWA servo control system

- Processing capacity of 2000 - 2200 running meters/8 hours (6,500 - 7,200 ft/8h shift)

- Automatic in-feed magazine with a capacity of 10 profiles

- Average cycle time for single cut : 12-16 sec/pc.

- Pneumatic gripper with 2 axis servo adjustment and rotation for accurate positioning of the profiles

- Ø 500mm (19.7") saw blade

- Cycle spray mist device

- Fully enclosed operation with safety guard

- Spare Ø 500mm (19.7") saw blade

- 20 litres (5.3 gal) pail of cutting fluid

- Aluminum dust & chips collector

- Label printer

- Inclined conveyor to remove scrap pieces and chips