We will get back to you shortly

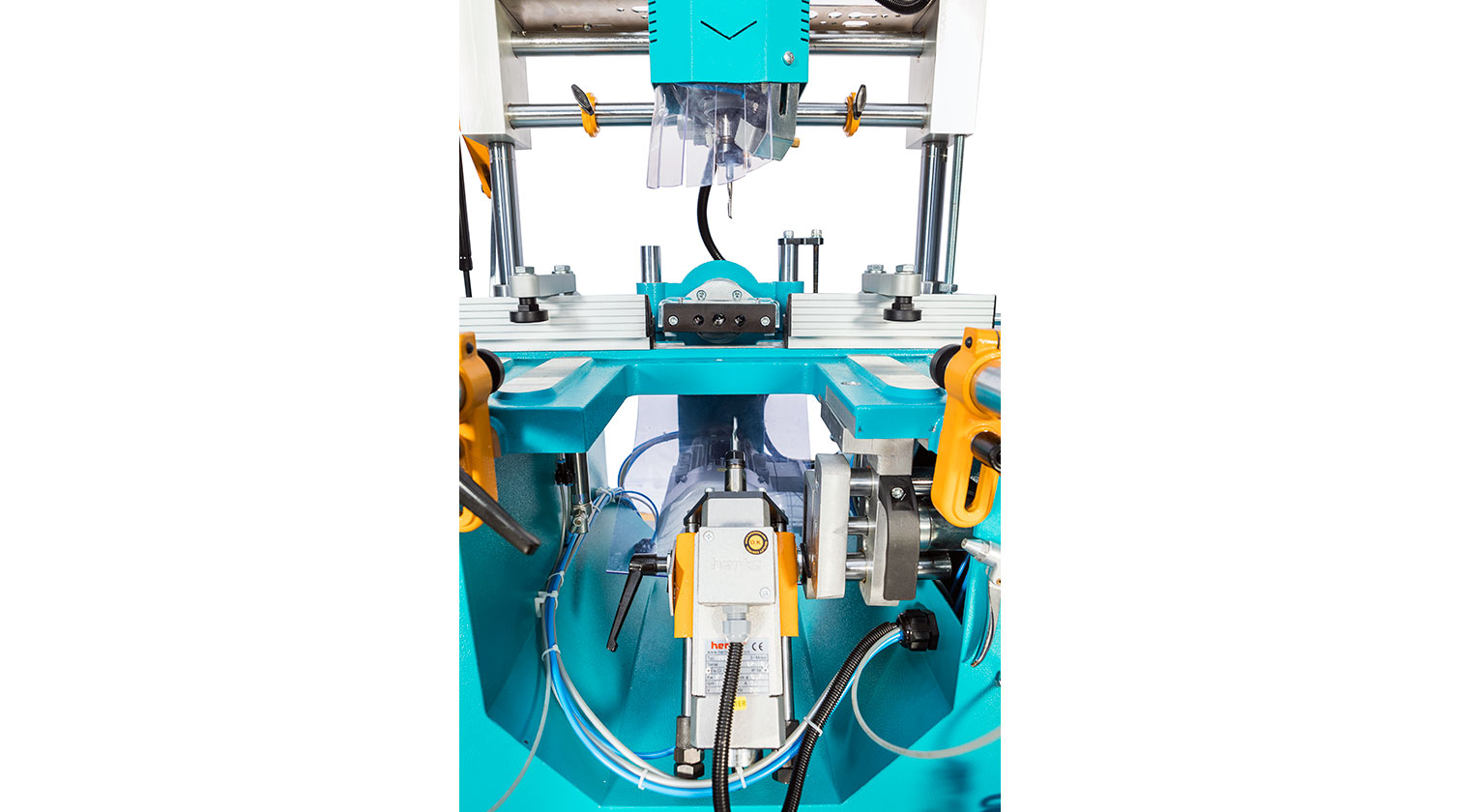

Copy Router | YILMAZ CRM 201 S

Combination of vertical spindle copy router with 1:1 transfer ratio from template to the workpiece, triple drill for “Tilt & Turn” windows and automatic water slot router unit. The “CRM 201 S” is capable to process slots for locks, handles, hinges and similar hardware cut-outs, water drain slots on PVC and aluminum profiles. The vertical router is operated manually by means of two handles: one for plunging in while the other to route on two axis. The copy router features high frequency direct drive motor and spray mist tool cooling system. Triple drill and water slot units operate automatically. Aluminum profiles up to 3mm (0.12″) wall thickness can be machined.

- Cast aluminum main structure

- Corrosion resistant linear guides

- Robust machine stand

- Electroplated copy template

- Two pieces tracer pins

- Slots can be machined without using the copy template by setting mechanical stops

- Side shafts with reference stops

- In-feed and out-feed workpiece supports

- Ergonomic hand control unit

- Router motor is controlled from the handle

- Cutting fluid is controlled from the handle and sprayed on to the work-piece manually

- Vertical high frequency spindle: 1 kW (1.35 HP), 230V, 1 Phase, 60 Hz

- Water slot high frequency spindle motor: 0.55kW (0.75HP), 230V, 1 Phase, 60 Hz

- Spindles speed (vertical + water slot): 18000RPM

- Triple drill motor: 0.75kW (1HP), 900 RPM

- Max machining (X,Y,Z): 300x170x130 mm (11.8"x6.7"x5.1")

- Min profile height: 30mm (1.18")

- Clamping capacity: 160mm (6.3”)

- Aluminium profiles with wall thickness up to 3mm (0.12") can be machined in 1:1 ratio

- Air consumption: 8 lt./min (1.8 gal/min)

- Air supply pressure: 6-8 bar (87-116 psi)

- 1 x Standard template

- 1 Ø5mm (0.197”), L: 80mm (3.15”) router bit

- 1 x 8mm collet

- 1 x Air blower gun

- 2 x Profile length stops

- 1 Spray mist tool lubrication system

- 2 horizontal pneumatic clamps

- 2 vertical pneumatic clamps

- 20 litres (5.3 gal) pail of cutting fluid

- MKN 300 roller conveyor - 3m (10')

- Additional router bits

- MA 240 centring device