We will get back to you shortly

Cutting and Punching Machine | PRESSTA-EISELE PROFILMA 501 EST

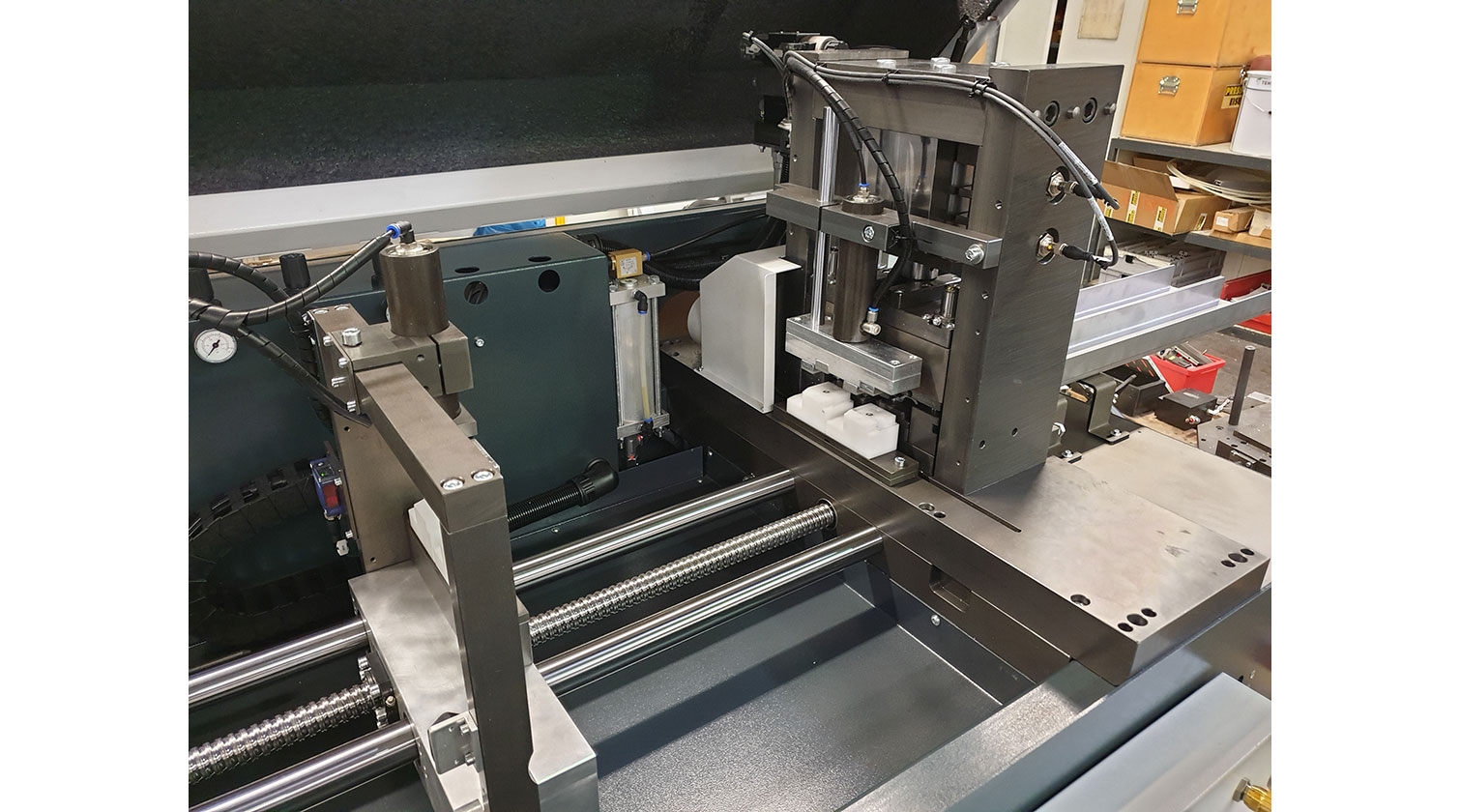

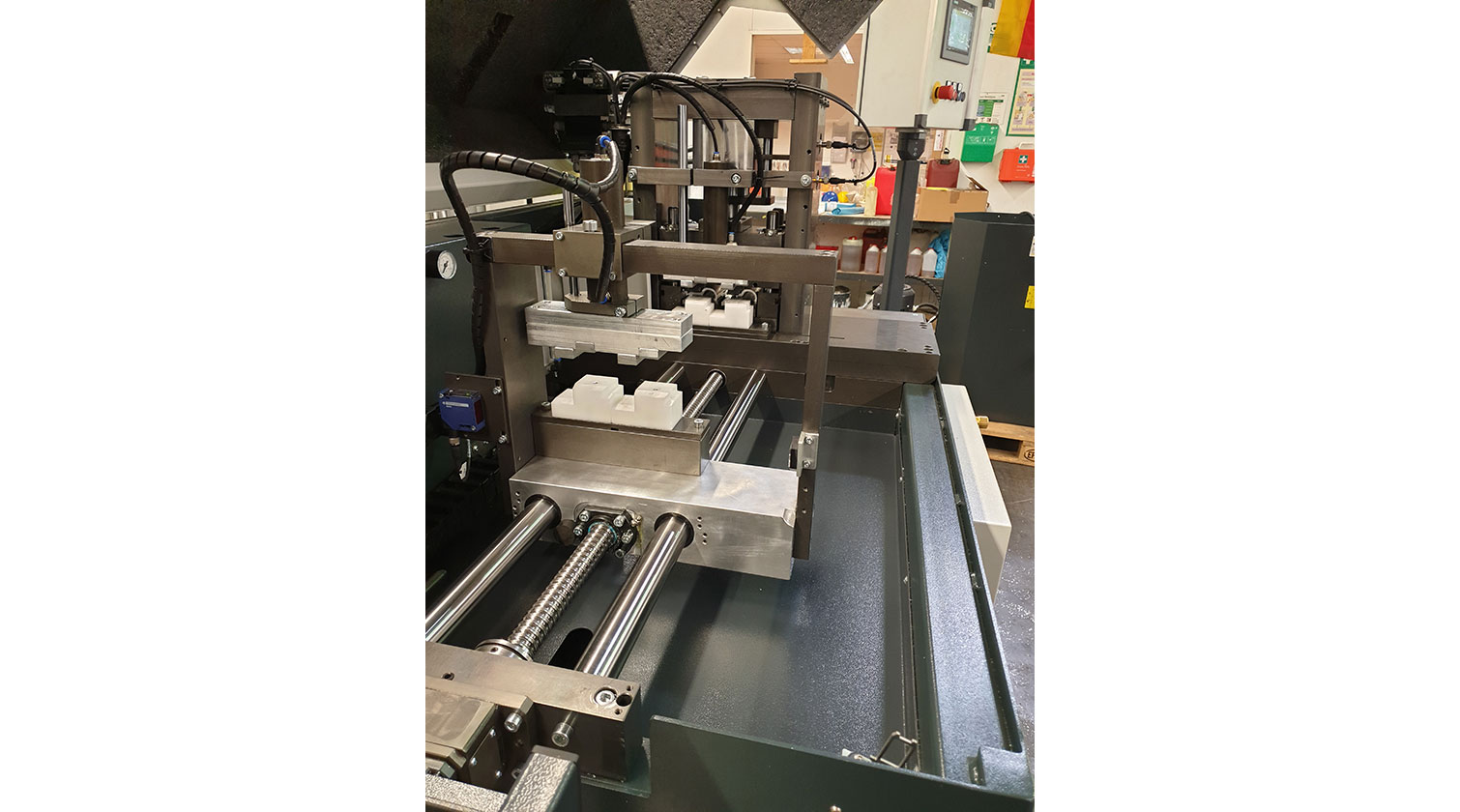

Pressta-Eisele Profilma 501E/ST is a fully automatic circular saw combined with a punching unit. Designed for cutting and punching aluminum profiles. It has an integrated servo bar feeder with 600mm stroke that is capable to cut max. 9900mm (32.1’ -with repetitive strokes) pieces automatically. Saw blade feed is performed by an hydro-pneumatic actuator and blade feed speed is adjustable. Vertical punching unit is mounted after the saw blade. Machine can process single or multiple profiles simultaneously depending on the profile. Profile guides and punching tools and clamping mechanisms are designed as per given drawings and criterion. An optional clamp kit is available in order to use the machine as an automatic saw only (must be specified at the order).

Work cycle: Material is aligned with cutting line and program is started. The material is clamped by the feeder and the clamp on the left side of the saw blade to make the trim cut. After trim cut, the material is fed into the die, punched and kept clamped by the punching unit and the clamp on the right side of the blade until the cut is completed. Punch die opens and feeder advances for the next cycle that also pushes punched part out. Processed parts exit the machine through a metal slide and free fall in to a customer provided bin/table. An optional vibrating outfeed conveyor is available to separate the chips from workpieces.

- Fully automatic cutting and punching as per given drawings (exact dwg/dxf files required)

- Hydro-pneumatic blade feed with infinitely adjustable feed speed

- Linear motion system consisting of precision round guides and ball screw.

- Hydraulic punch unit right after saw blade with one vertical punch cylinder

- Punching force: 150 kN, cylinder stroke 20mm, cycle time per up/down punch stroke = 3s

- Scrap pieces from punching process fall under the machine base

- PLC controlled automatic lubrication for punching tool

- Adjustable horizontal and vertical clamping pressure

- Piece count indication with bundle multiplier and cycle time indication on the control display

- Automatic stopping function when the profile finished

- Cycle spray mist device, oil tank 1 Litre capacity with automatic stop if fluid ends

- Part evacuation slide at the out-feed side of the machine, 200mm (7.9") long

- Noise reduction provided by noise absorbing mats mounted inside the machine

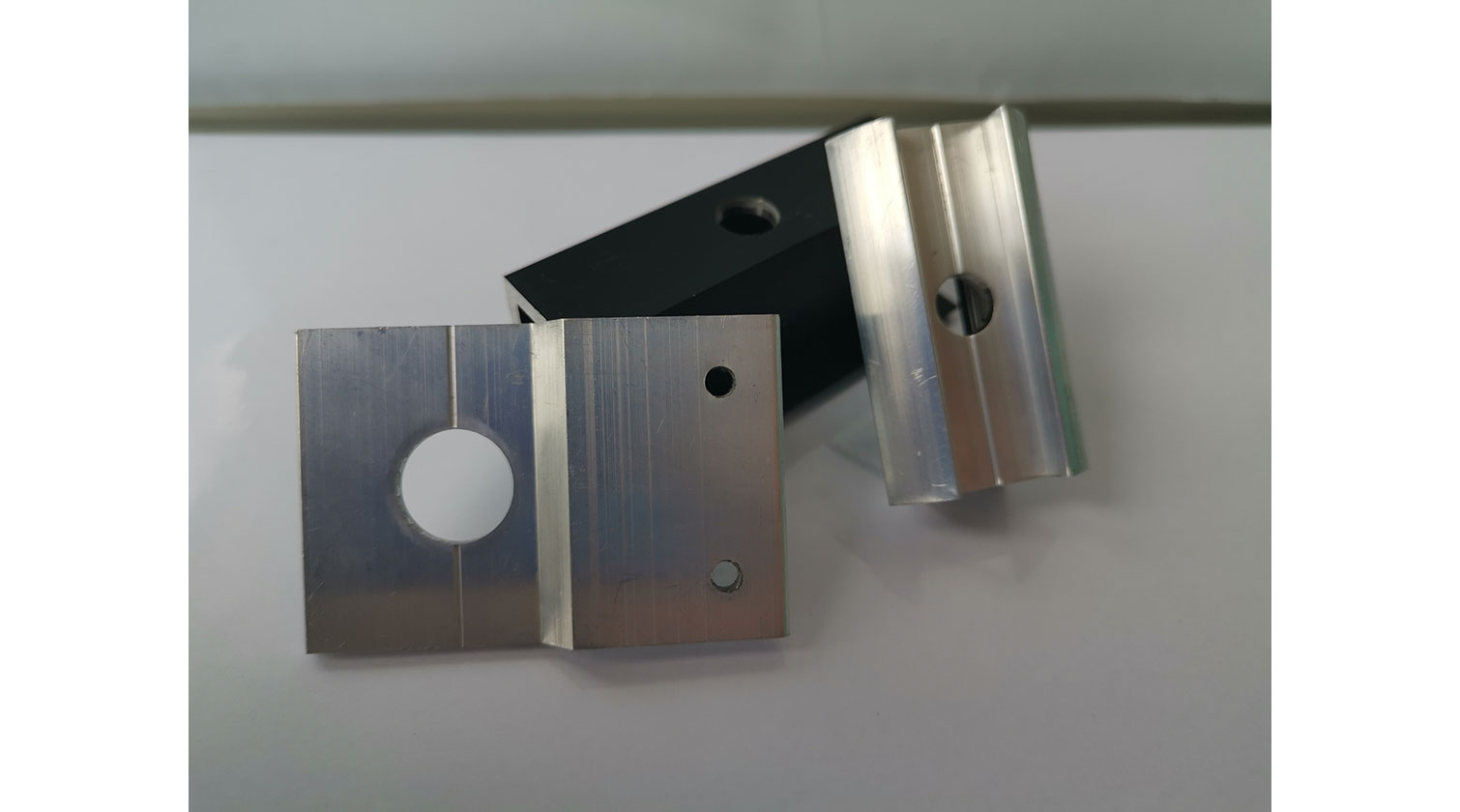

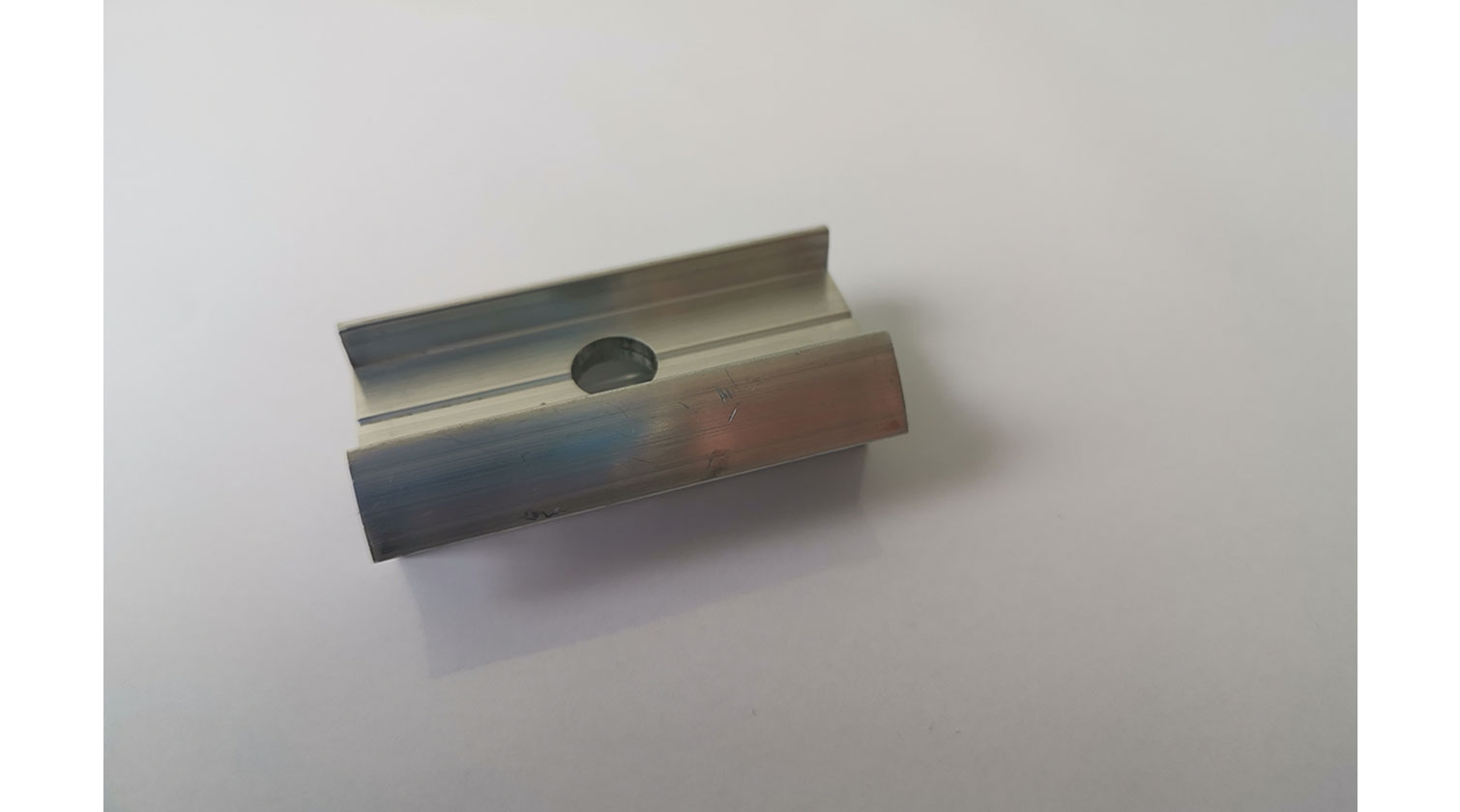

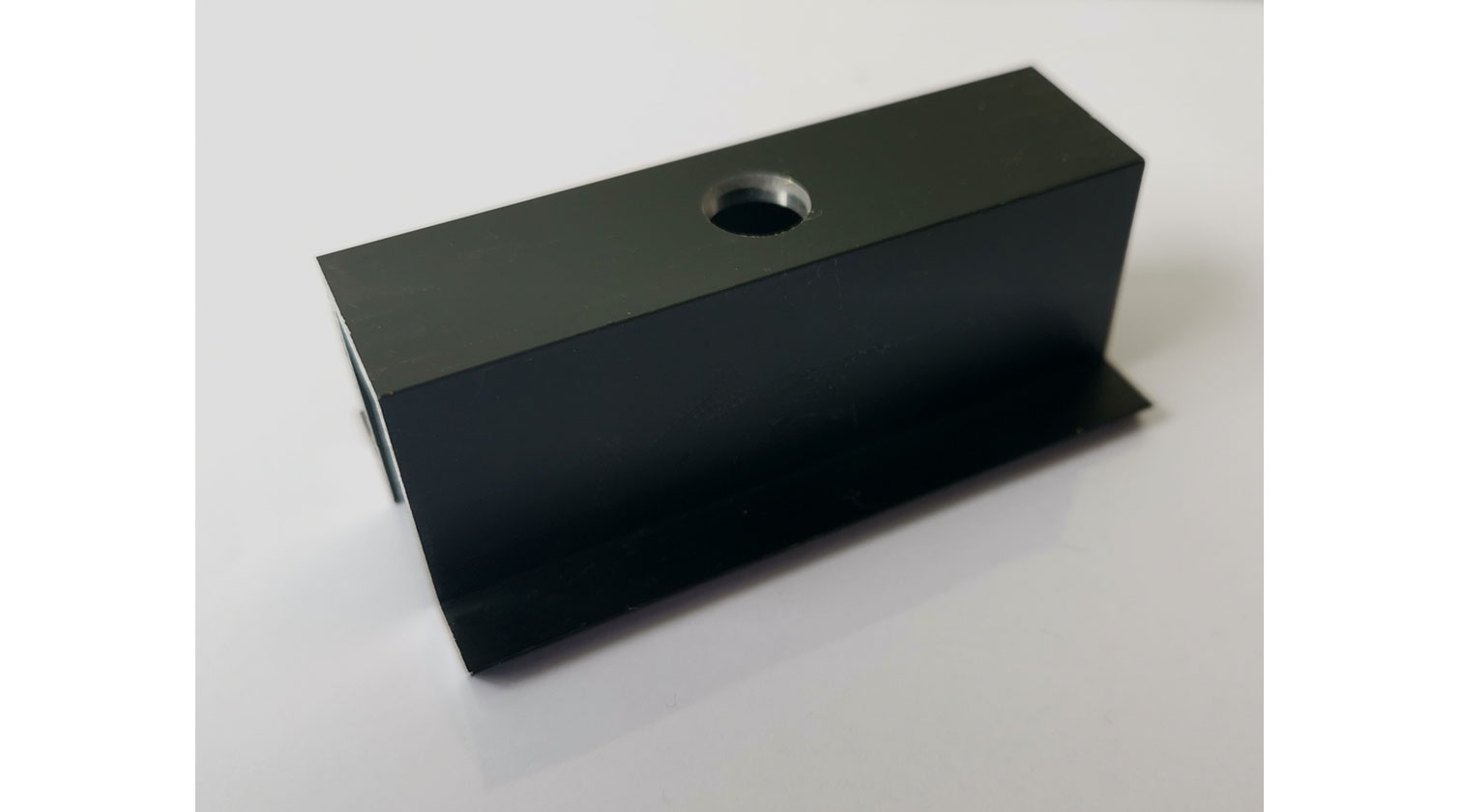

- All necessary fixtures, profile guides and inserts are designed and manufactured by Pressta-Eisele for the entire range of profiles of customer to be ran on this machine

- Fully enclosed operation with tunnel in-feed guard

- Motor: 7,5 kW, S6, 400V, 50Hz, 2850 RPM

- A transformer for 600V Canadian power is supplied with the machine

- Ø 550mm (21.6") saw blade, up stroke cutting direction

- Max cutting size (WxH): 270x140mm (10.6" x 5½") - ∅ 185mm (7.3")

- Servo material feeder with 600mm (23.6") stroke, equipped with horizontal and vertical pneumatic clamps.

- Max. cutting length up to 9.9m (32½') using repetitive strokes

- Remaining piece length down to 100mm (4") depending on the profile

- 2 x Ø100mm (4") suction port to connect chip extractor

- Ø 550mm (21.6") saw blade

- Vertical and horizontal pneumatic clamps both on the left and right side of the blade

- 2 x Ø100mm suction port to connect chip extractor

- Cycle spray mist device

- Fully enclosed operation with tunnel in-feed safety guard

- Spare Ø 550mm (21.6") saw blade

- 20 litres (5.3 gal) pail of cutting fluid

- Aluminum dust & chips collector

- Idle roller conveyors