We will get back to you shortly

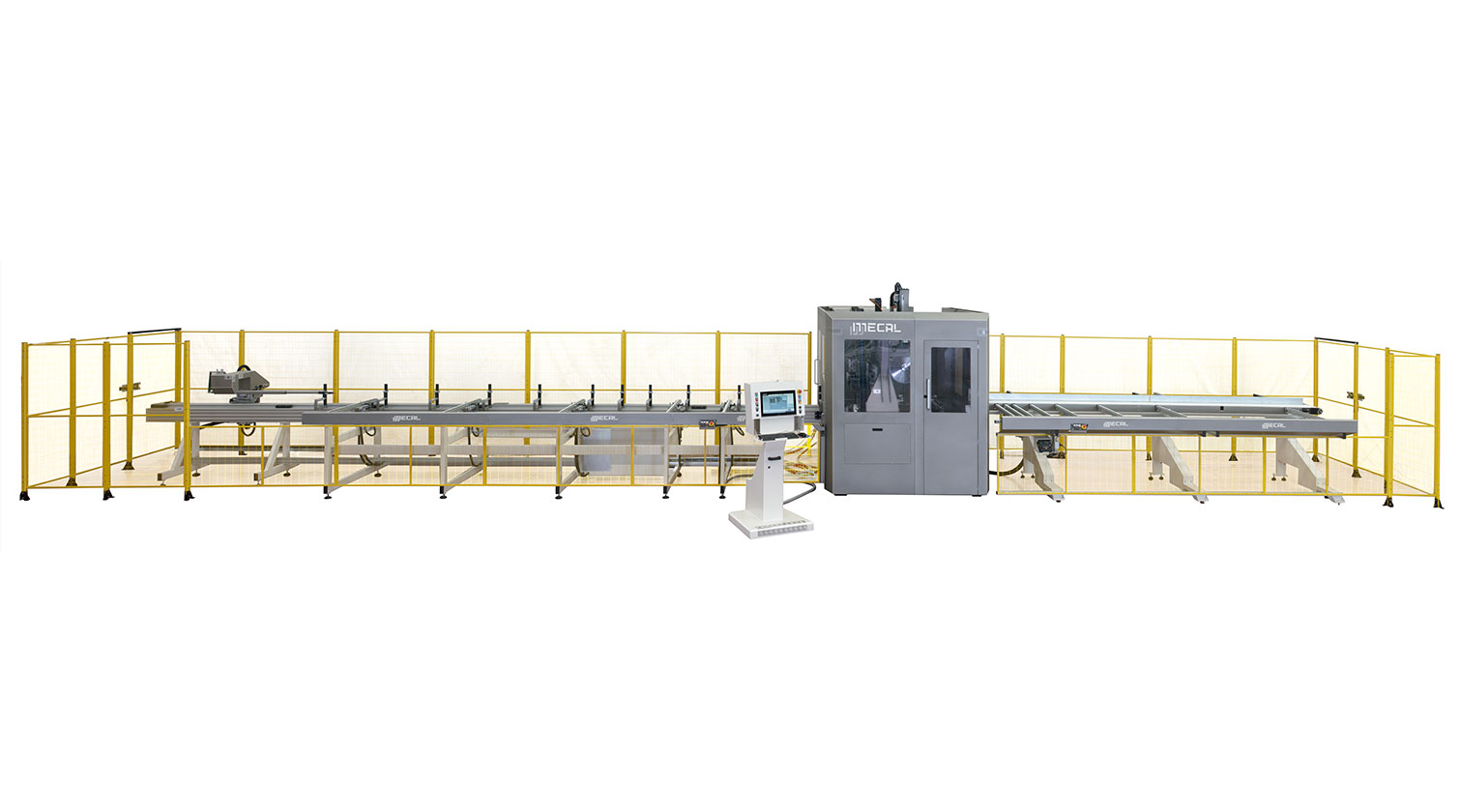

Feed-through Aluminum Profile Fabrication Centre | MECAL MC 316

Mecal “MC 316” fabrication centre has been designed for automatic milling, drilling, tapping and cutting operations on aluminum profiles. The unit consists of a loading magazine, servo material pusher, machining station, cutting station, and motorized unloading table.

The operators will load multiple stock lengths on the in-feed table. The profiles are fed one at a time through the rotating ring style (turret) milling/drilling station equipped with multiple electro-spindles. Machine features horizontal and vertical clamping systems to hold down the extrusion during the machining and cutting. After the milling, the pusher advances and the cut is performed by a ∅ 550mm (21.6″) blade capable to make straight, miter cuts and notches. After cutting, the parts are transferred onto a belt conveyor which then carries them out from the cutting station. A pneumatic pusher will move the parts cross wise on the out-feed table.

GENERAL

Mecal “MC 316” is a feed-trough aluminum CNC fabrication centre designed for milling, drilling, tapping and cutting operations on aluminum profiles. The whole system consists of a loading magazine, servo material pusher, machining station, cutting station, and motorized unloading table.

LOADING MAGAZINE

The operator loads multiple stock lengths on the in-feed magazine.

Operator aligns the profile by using the reference plate located on the right end of the table as well as by pulling the profile towards him against the reference stops.

Motorized belt conveyor advances until the first profile reaches the feeding area, then pneumatic alignment rollers clamp and align the extrusion.

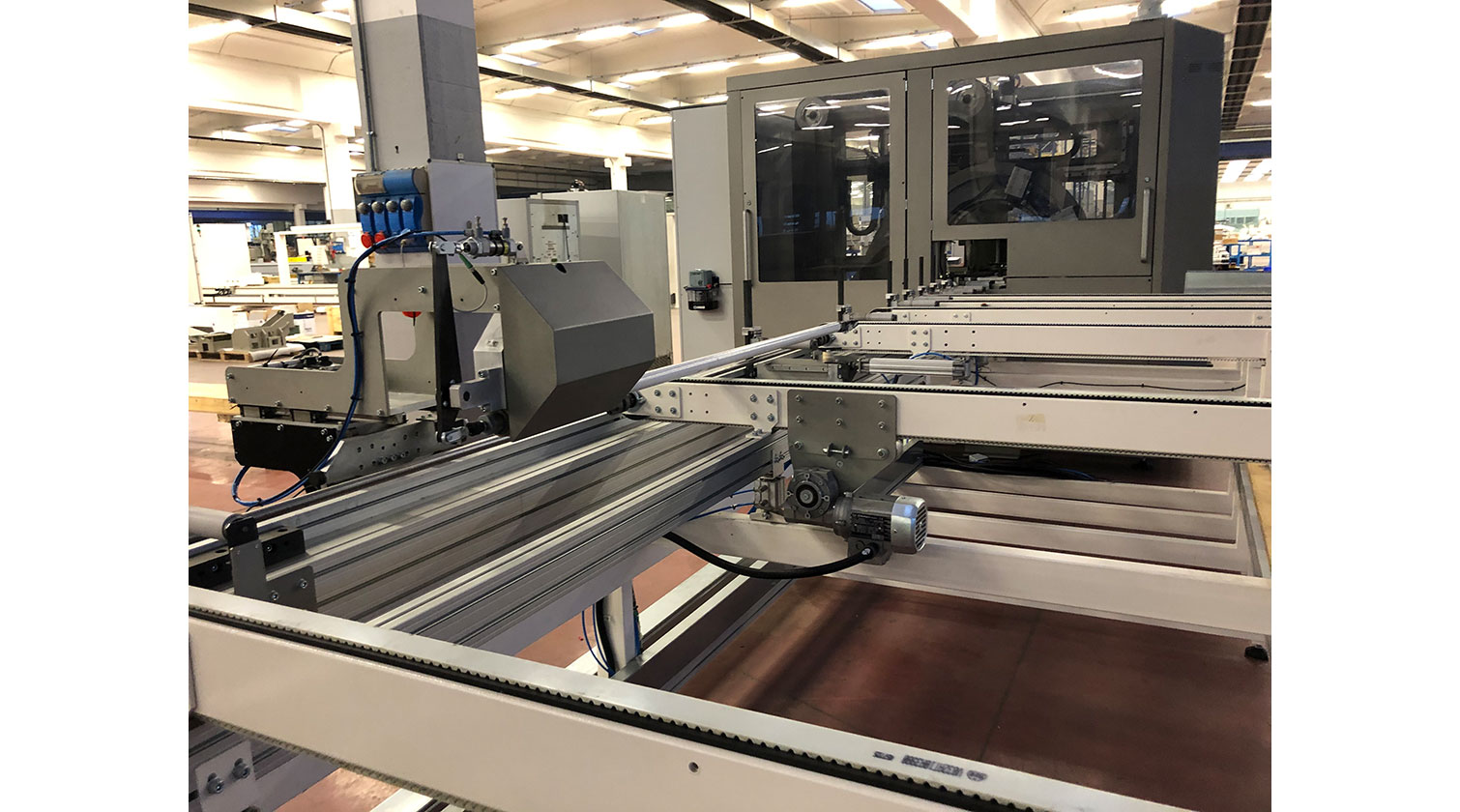

PROFILE FEEDING

Profiles on the loading table are automatically fed into the machining and cutting unit by a servo controlled pusher. The linear motion system is consisting of profiled linear guides, linear bearings and a high precision helical rack and pinion drive.

The pusher is equipped with a gripper arm that can be adjusted both vertically and horizontally by servo motors. Optionally, the gripper arm can also rotate around its axis within 0°-180°.

Low friction plastic rollers avoid any possible scratch supporting the profiles while fed in the milling and cutting stations. Vertical rubber rollers properly guide the extrusions during the feeding process.

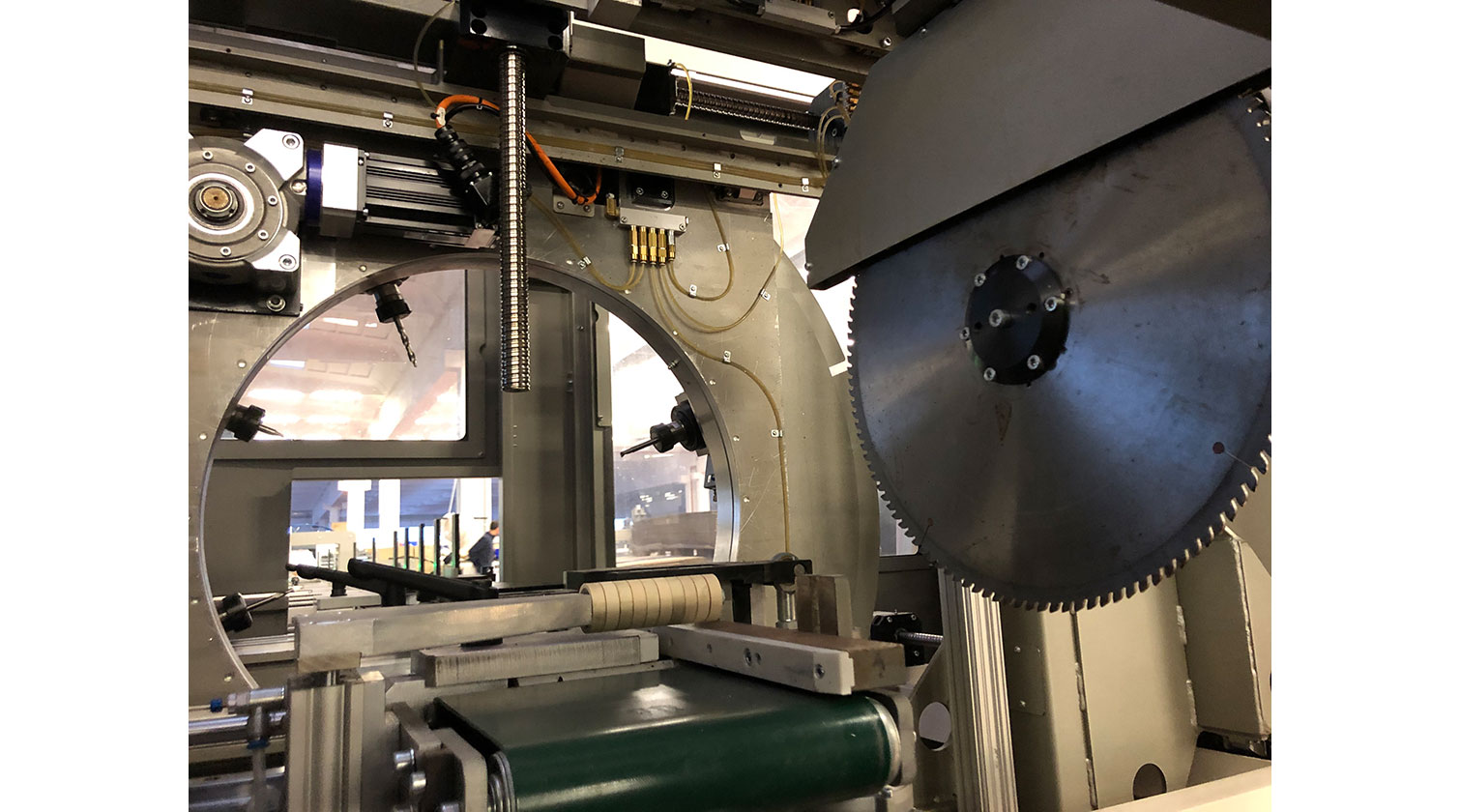

MILLING AND DRILLING UNIT

The milling/drilling unit features a rotating ring (turret) equipped with 4 electro-spindles (6 as optional). The turret can rotate continuously from 0° to 380° (-190° +190°) controlled by CNC. Tool cooling is provided by an MQL (Minimum Quantity Lubrication) system. The profiles are automatically fed one at a time through the rotating turret. An horizontal and vertical clamping systems holds down the extrusion while performing machining and cutting operations in order to minimize vibrations.

CUTTING UNIT

After the milling, the pusher advances and a 550mm blade performs straight, miter cuts and notches. The cutting unit features a CNC controlled descending motion as well as horizontal and vertical clamps. Venturi type blade lubrication.

UNLOADING TABLE

A narrow belt conveyor carries the machined part out of the cutting station. When the part is completely ejected, the conveyor belt stops and the pusher moves the finished part on a motorized cross belt conveyor that will advance step by step. These belts are wear resistant and have low friction coefficient.

Mecal “MC 316” feed-trough aluminum CNC fabrication centre is the ultimate goal for the manufacturers that are looking to maximize their volumes along with the automation, thus the ideal solution for aluminum window manufacturing.

- In-feed loading magazine, servo material pusher, machining station, cutting station, and motorized out-feed table

- Gripper arm can be adjusted in height and width by servo motors

- Tracks equipped with low friction plastic rollers to avoid scratches

- 4 CNC axis: X-Y-Z-A

- All the electro-spindles are mounted on a rotating ring (turret)

- Tool cooling is provided by an MQL (Minimum Quantity Lubrication) system

- Automatic centralized lubrication system for all guides, ball screws and linear bearings

- Maximum stock length: 7200mm (23.6')

- Minimum stock length: 1000mm (3.3')

- Maximum total loading width on the in-feed table: 2200mm (7.2')

- Max. total loading weight on the in-feed table: 500kg (1100 lbs)

- Gripper/pusher: 3 CNC axes (U, V, W)

- U Axis (Bar feeding) stroke: 9350mm (30.7')

- V Axis (Horizontal adjustment) stroke: 225 mm (8.85")

- W Axis (Vertical adjustment) stroke: 200 mm (7.87")

- C Axis (Gripper rotation) range: 0° - 180° (optional)

- Rotating ring (turret): 4 CNC axis: X-Y-Z-A

- Spindle power (each): 4,5kW

- Spindles speed: 24000 RPM

- Machining capacity of the profile W: 250mm (9.84")

- Machining capacity of the profile H: 150mm (5.9")

- Turret can rotate continuously from 0° to 380° (-190° +190°)

- Cutting unit: 3 CNC axis: up/down, forth/back and rotate

- Blade rotation range: 180° (-/+90°)

- Saw blade: ∅ 550mm (21.6")

- Cutting capacity of the profile W: 250mm (9.84")

- Cutting capacity of the profile H: 150mm (5.9")

- Saw blade motor: 2.7 kW

- Minimum cutting length at 90° = 0

- Minimum cutting length at 45°/ 135°: 370 mm (14.5") - to unload automatically on the out-feed table

- Unloading table: 5000x1700mm (16.4'x5.6')

- PC Desktop, Windows 10, monitor TFT-LCD

- Cross loading conveyor belt

- Pusher/gripper arm

- Standard number of electro spindles: 4

- Air-cooling for electro-spindles

- Automatic centralized lubrication system

- Saw blade: ∅ 550mm (21.6")

- Unloading cross transfer table

- PC Desktop, Windows 10, monitor TFT-LCD, keyboard QWERTY, mouse USB

- Cross transfer loading conveyor: longer length available upon request

- C Axis (pusher/gripper rotation) range: 0° - 180°

- Unloading table: 7200x1700mm (23.6'x5.6')

- Bar code printer

- Spare blade ∅ 550mm (21.6")

- 20 litres (5.3 gal) pail of cutting fluid