We will get back to you shortly

Double Mitre Saw | MECAL TDC 622 DYNACUT

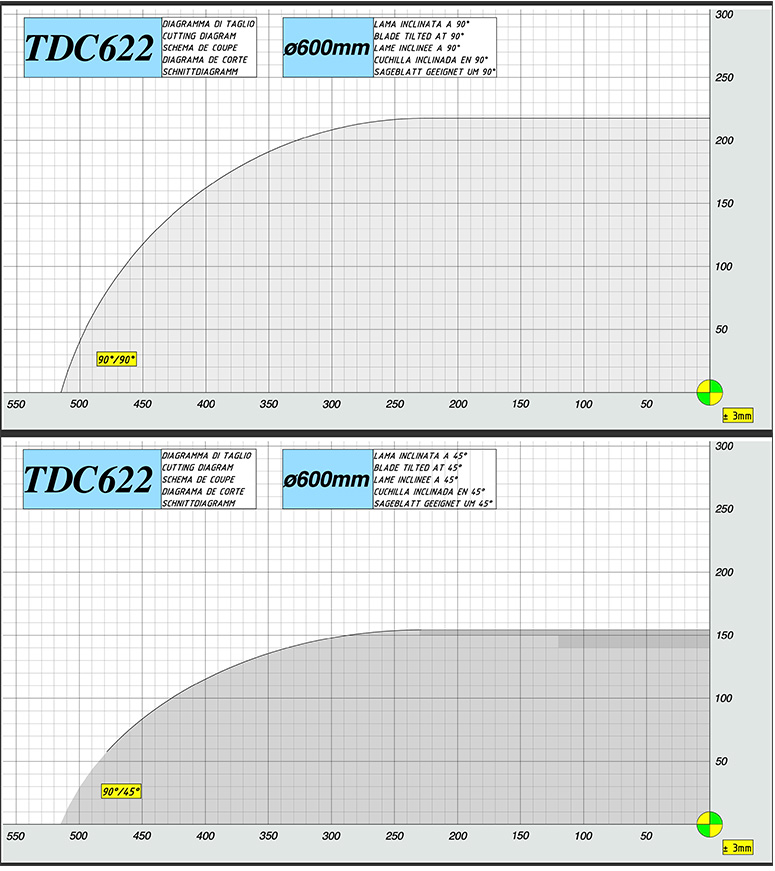

The “TDC 622 Dynacut” is an up-stroke wide cut double mitre saw. The saw is equipped with 600mm (23.6″) blades and features a radial movement of the blades providing one of the widest cut available on the market. Cutting heads can automatically and independently tilt within 90° and 45° inward. Left cutting unit is stationary, while the right one is motorized and moves along the whole length of the saw. The “TDC 622 Dynacut” is available in 5000mm (16.4′) and 6000mm (20′) lengths.

GENERAL

The Mecal “TDC 622 Dynacut” is an up-stroke double mitre saw ideal for applications such as curtain walls as well as industrial aluminum profile cutting. The saw can cut straight or mitre on aluminum extrusions.

The saw features a motorized right head positioning, while the left cutting unit is stationary. The 600mm (23.6″) saw blades in addition to the linear forth-back motion and the pivoting motion of the cutting heads allow this machine to achieve one of the largest cut capability in the market.

Machine is either 5m or 6m useful cutting length with double head simultaneously, nevertheless with a special function, it is possible to cut oversize lengths up to approximately twice the maximum cut length.

Cutting units can tilt electronically within 90° and 45° inward.

Two hand controlled sawing process and automatically operated safety guards ensure operator safety.

Cutting modes are: single cut, automatic cutting list processing, over-size and under-size cutting cycles.

Cutting lists can be entered on the machine pc, can be imported through a USB key or network.

OPERATION

To perform the cut, the operator must hold simultaneously two pushbuttons with both hands. As soon as the cut is performed and one button is released, the blades retract in their housing. Also hydro-pneumatic cylinders ensures a precise index of the blades.

SAFETIES

The Mecal “TDC 622 Dynacut” up-stroke double mitre saw is provided with two lifting covers (one each cutting head) as part of the standard safety features to provide full protection to the operator.

STANDARD ITEMS/FEATURES

- Industrial computer MS Windows compatible

- 3m (10′) mobile roller conveyor

- 2 x TCT saw blade Ø 600 x 32 x 4,4/3,9 mm

- Minimal Quantity Lubrication system (MQL) for blade lubrication

- 2 pairs of vertical pneumatic clamps

- Adjustable profile back support

- Outlets to connect a dust collector

- Compressed air treatment group

- Service wrenches

- User’s manual

- Transformer to run with 600V-60Hz power

- Servo tilting of the cutting units up to 45° towards inside variably

- Standard cutting cycle with only pivoting motion of the saw blades

- Dynamic cutting cycle with the compound motion of the saw blades. This case, pivoting motion is combined with linear advance and retract motion of blade to increase cutting capacity

- Hydro‐pneumatic blade feed for both pivoting and linear movements

- Dynamic protection guards for a complete coverage of the cutting area

- Dynamic profile back support automatically adjusts according to the cutting angle in order to achieve best possible material backing.

- Clamping system of the profile is linked to the angular positions of the cutting units so that the optimum clamping position is automatically set as the blades are adjusted

- Minimal Quantity Lubrication system (MQL) for blade lubrication

- Pre‐arranged to connect a suction unit for chips and fumes

- Servo tilting of the cutting units up to 45° towards inside variably

- 2 x 5kW, 400V, 50-60 Hz, 3 Phase Motors

- Mobile roller conveyor (3m)

- 2 x TCT saw blade Ø 600mm (23.6")

- Blade speed: 2800 RPM

- Minimum cutting length at 90°: 390mm (15.35")

- Maximum cutting length (single stroke): 5000mm (16.4')

- Operating air pressure: 7 Bar (101 psi)

- Industrial computer 15"

- Mobile roller conveyor 3000mm (10")

- 2 x TCT saw blade Ø 600mm (23.6")

- 2 pairs of vertical pneumatic clamps

- 2 pairs of horizontal pneumatic clamps

- Compressed air treatment group (Air filter/Lubricator/Regulator)

- Spare Ø 600mm (23.6") saw blade

- 20 litres (5.3 gal) pail of cutting fluid

- Automatic intermediate support

- Barcode printer

- Barcode scanner

- Industrial dust collector